- The pump is driven by a DC motor.

- The transformer for AC operation is built into the connection cap.

- As it is in protection class 2, no earth conductor is required.

DANGER! Electric shock can kill!

- Work on the electrics must be carried out only by authorised contractors.

- Disconnect the pump from the power supply and secure against reconnection.

- Check that no voltage is present.

WARNING! Risk of fire due to electrical ignition!

- Ensure that the pump is connected only to the power supply specified on the type plate.

- A permanent connection to the power supply is possible; alternatively use a mains plug with IP 44 rating (provide all-pole disconnection).

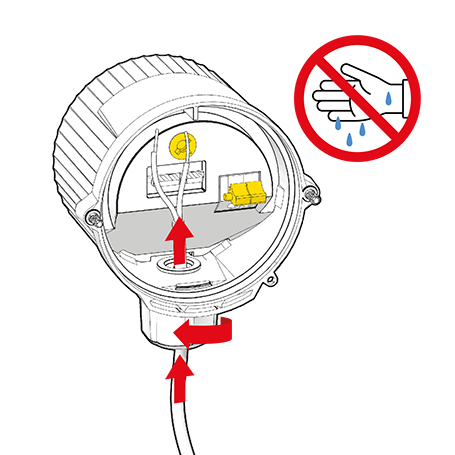

- Round cable diameter 5–8 mm

- Wire cross-section 0.75–1.5 mm2

- Strip 8.5–10 mm of insulator from the ends of the wires.

- Twist the wire ends; do not use wire-end sleeves or tinned ends.

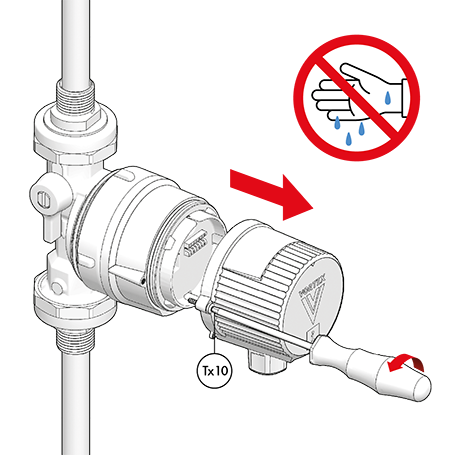

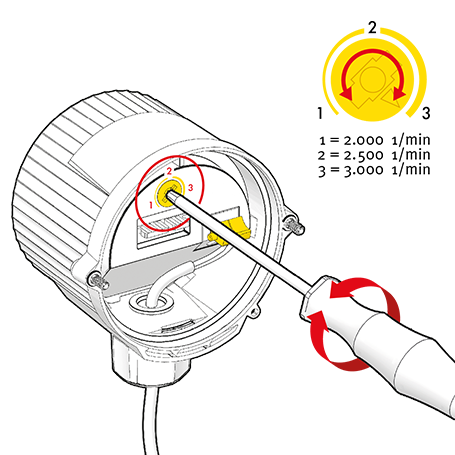

Undo the module cap with a TX10 screwdriver.

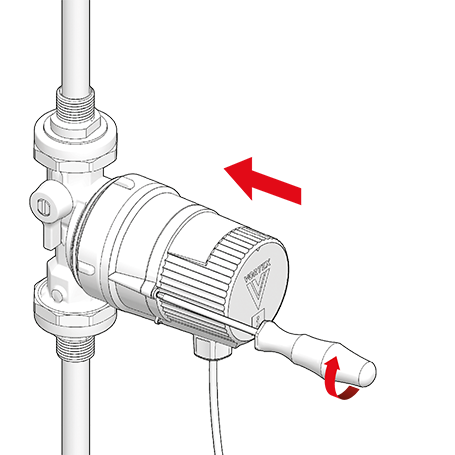

Undo the cap nut and insert the cable.

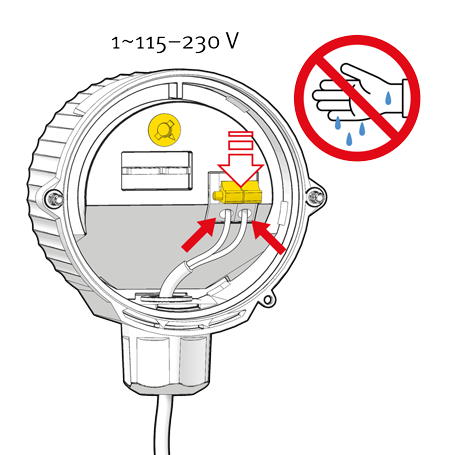

Push yellow lever forward and insert the wire into the red cable terminal. Release the lever again.

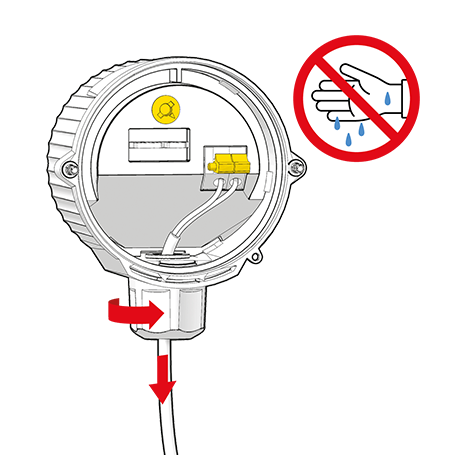

Allow a suitable length of cable and retighten the cap nut.

Adjust speed by turning the rotating yellow knob:

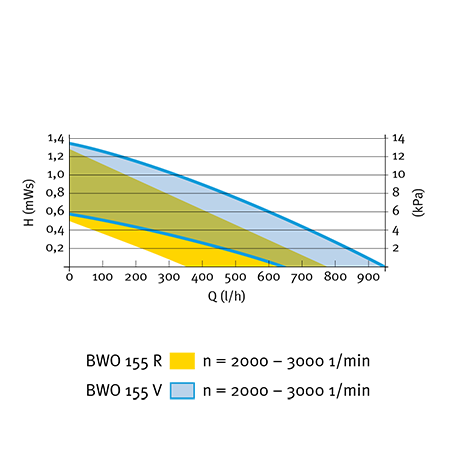

1 = min. speed (2000 rpm)

2 = medium speed (2500 rpm = factory setting)

3 = max. speed (3000 rpm), or use any intermediate position.

Screw the module cap on firmly.

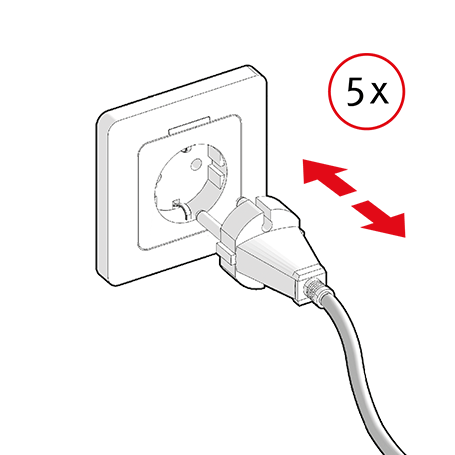

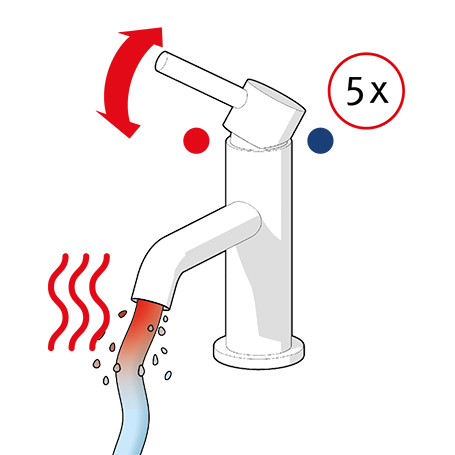

To vent any remaining air, switch the pump on and off several times …

… and open the DHW tap several times …

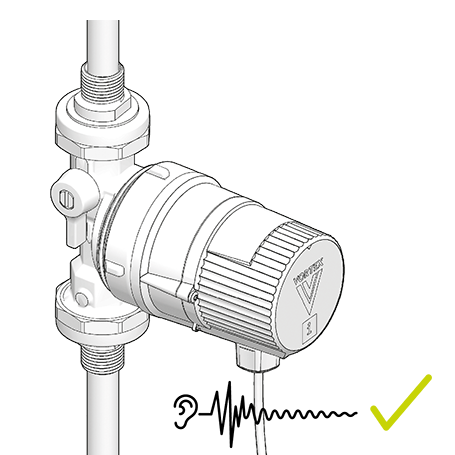

… until the pump runs quietly.