CAUTION! Ingress of water will cause physical damage!

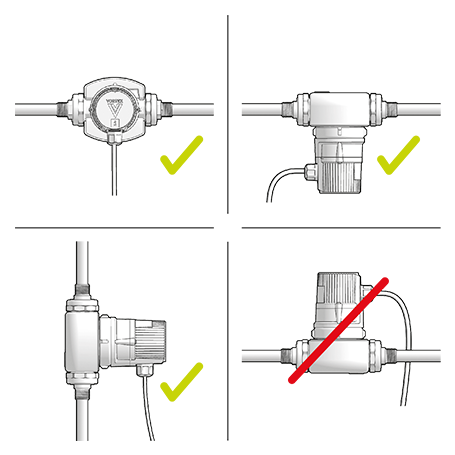

- Ensure that the cable entry and cable face downwards after installation.

Select a suitable installation site and permissible installation position.

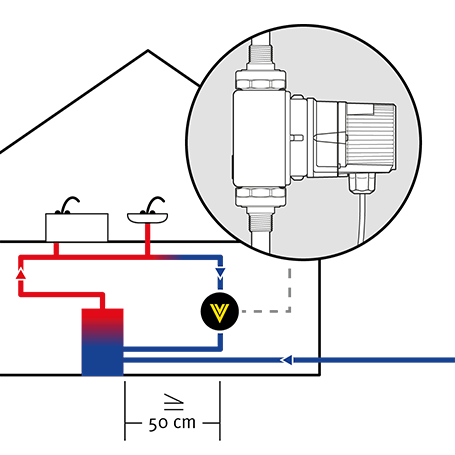

Avoid exposing pumps with thermostatic functions, such as the ERT or SL, to heat:

– Maintain a clearance of at least 50 cm from the DHW heater.

– If the return line opens vertically into the cylinder, install the pump well away from the cylinder entry.

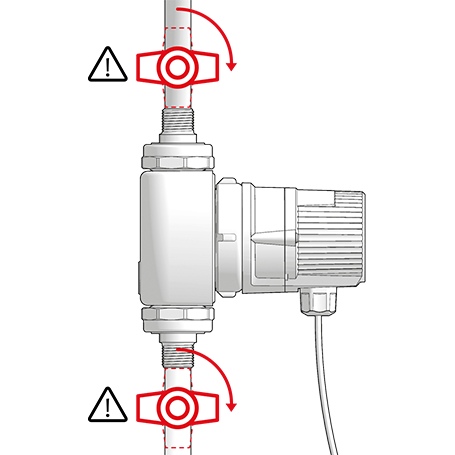

Fit shut-off valves and a non-return valve (Δpmax = 0.2 kPa or 20 mbar).

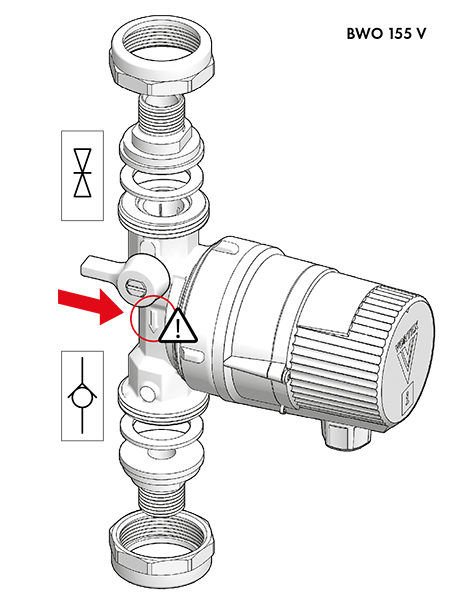

- The integrated shut-off valve in the V-pump housing and the Vortex screw-in valves are only provided to enable a brief shut-off while the motor is replaced.

Integral valves on V pumps

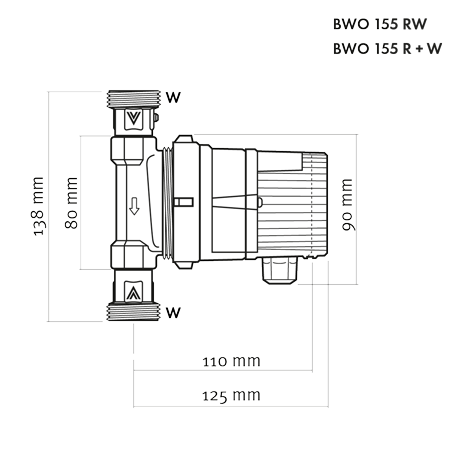

Optional screw-in valves on R pumps (W-valves)

- Integral screw-in valves on BWO 155 RW pump

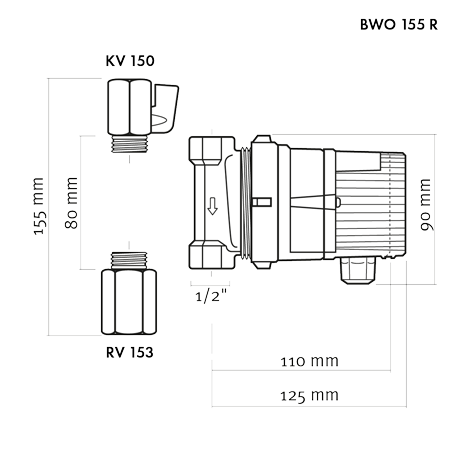

Optional screw-in valves on R pumps (RV 153, KV 150)

When installing the pump, ensure that it is not under strain.

- Observe correct direction of flow.

DANGER! Pressurised system!

- Before working on the motor or pump connections, close the shut-off valves.

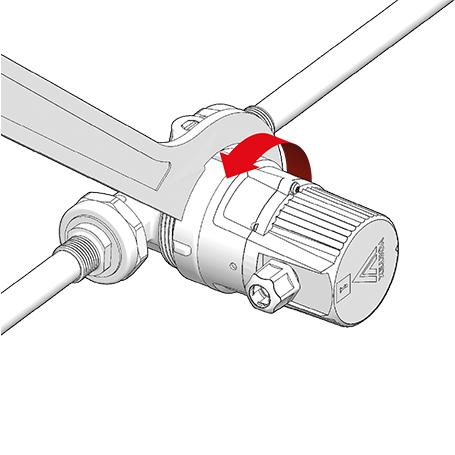

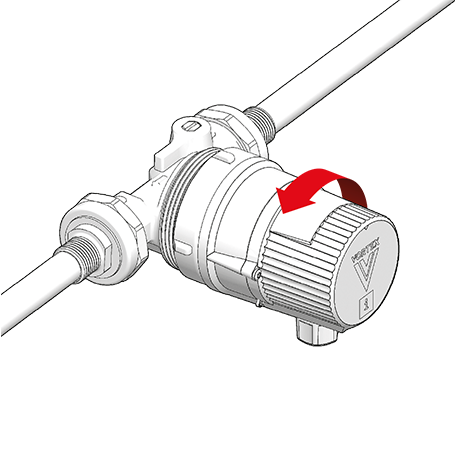

Rotate the pump control panel if necessary so that it is visible (cable exit underneath). To do so, slightly loosen the union nut …

… turn the motor …

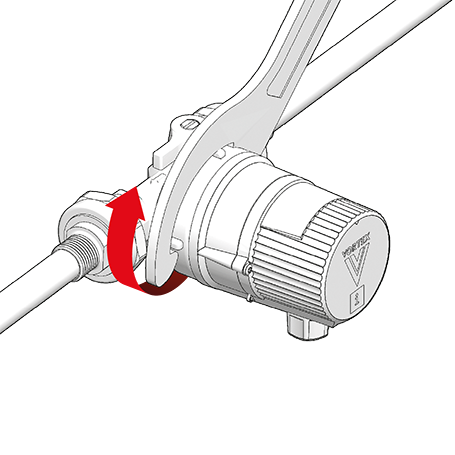

… and retighten the union nut (max. 20 Nm).

- Fully separating the motor from the pump housing is only necessary for maintenance purposes (see chapters ‘Flushing and venting’ and ‘Maintenance’).

- The pump has dry-running protection. If it runs largely in air, the PCB will repeatedly stop it to protect the rotor bearings. In a fully vented circulation circuit, the pump will run uninterrupted.