- The drive of the pump is a DC motor.

- For AC operation a transformer is integrated in the module cap.

- Due to protection class 2 a protective conductor (ground wire) is not required.

Danger! Danger of electrocution!

- Have all electrical work carried out by qualified personnel only.

- Disconnect motor from power supply and ensure it cannot be reconnected unintentionally.

- Check if pump is de-energized.

Warning! Fire hazard due to electrical ignition!

- Make sure that the pump is only connected to the power supply specified on the name plate.

- A permanent power supply is possible, alternatively use a mains plug with IP 44 rating (provide isolator that separates all poles).

- Round cable diameter 5 – 8 mm

- Cord diameter 0.75 – 1.5 mm2

- Strip cords by 8.5 – 10 mm.

- Twist wires (no wire end sleeves, no tinned ends).

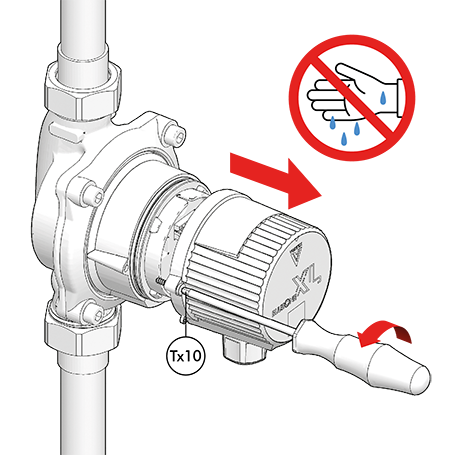

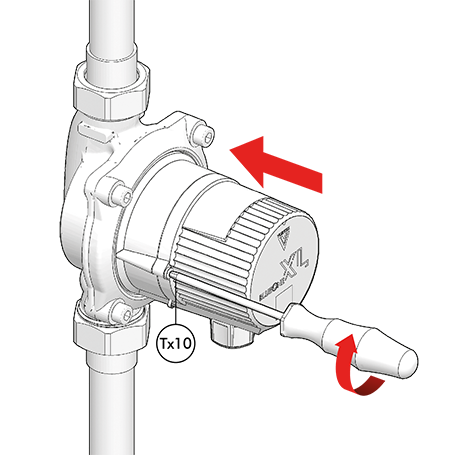

Undo module cap with a Tx10 screwdriver.

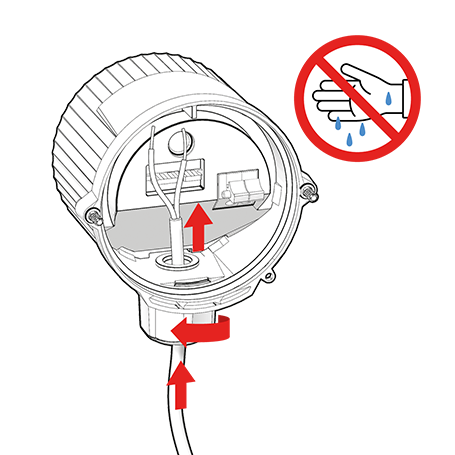

Loosen the cap nut and insert cable.

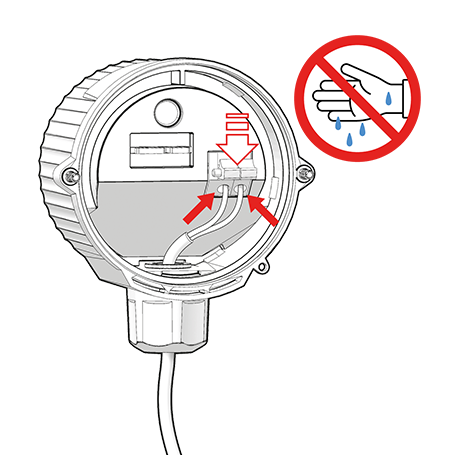

Push forward the yellow lever, insert cable wires into red clamp, then release the yellow lever again.

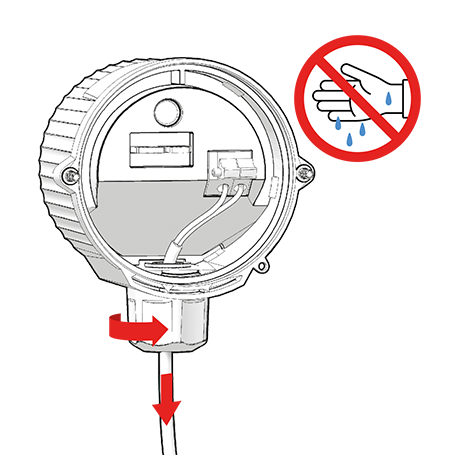

Arrange the cable properly inside the module cap, then refasten the cap nut.

Refasten the module cap.

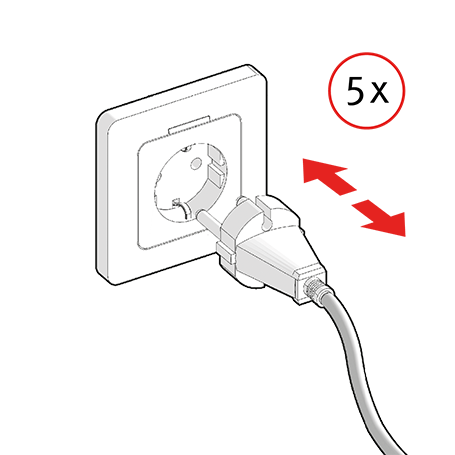

For final venting alternately turn the pump on and off …

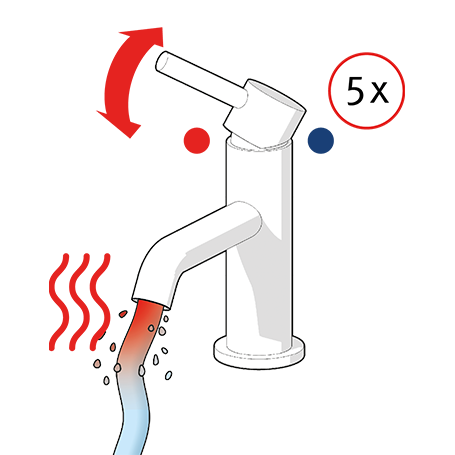

… and open and close hot water tap several times …

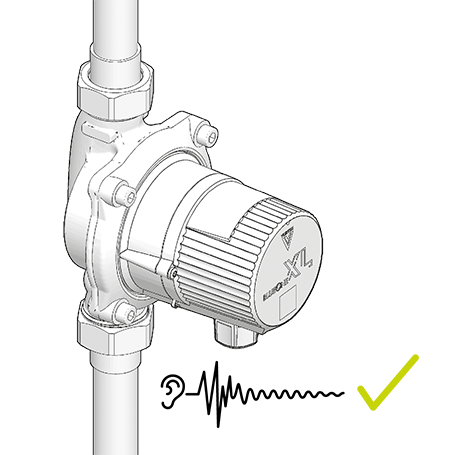

… until noiseless pump run is achieved.